tostadas

Hobbyist / Craftsman

It’s been a while since my last project thread. Cleaver time baby!

The Knife

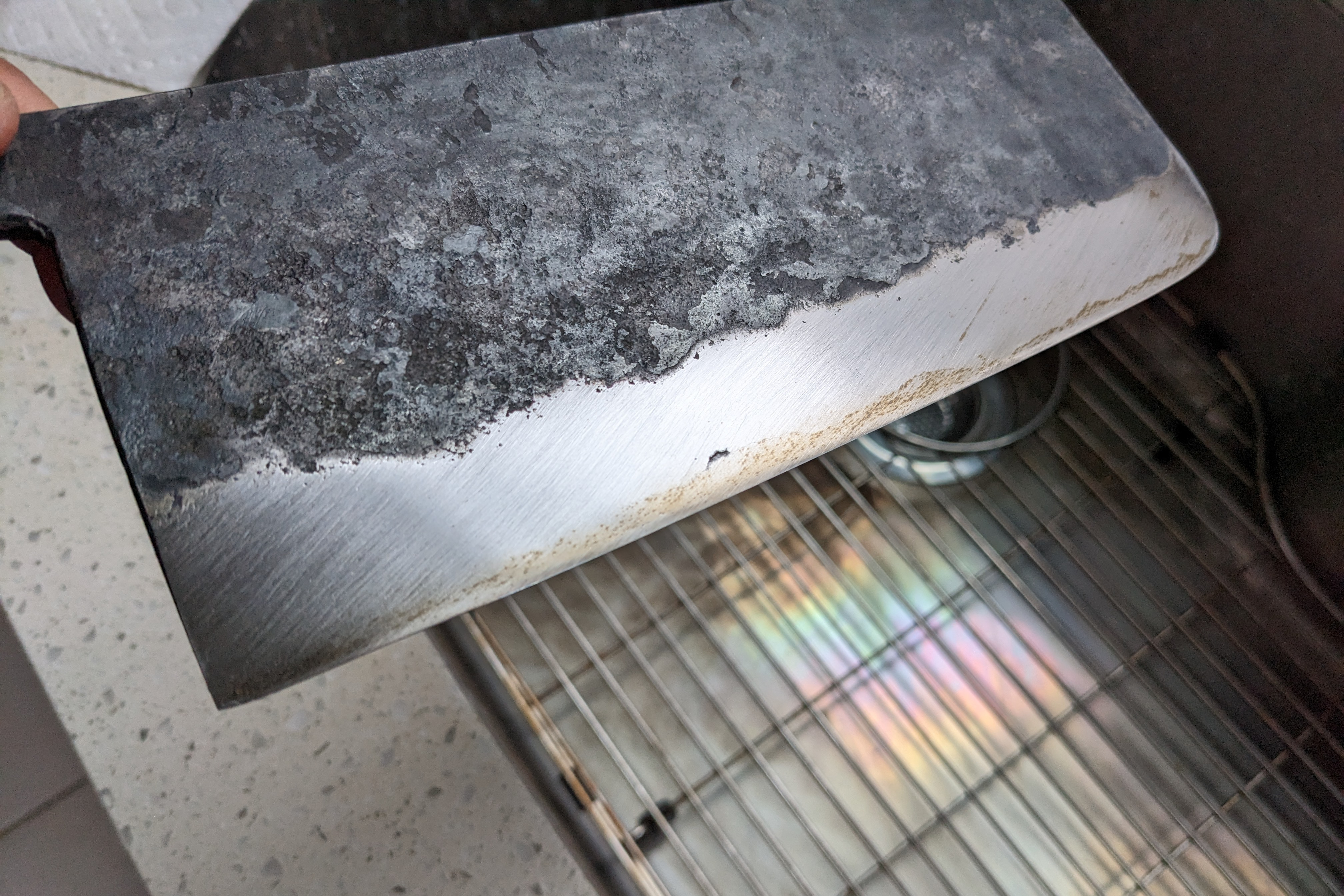

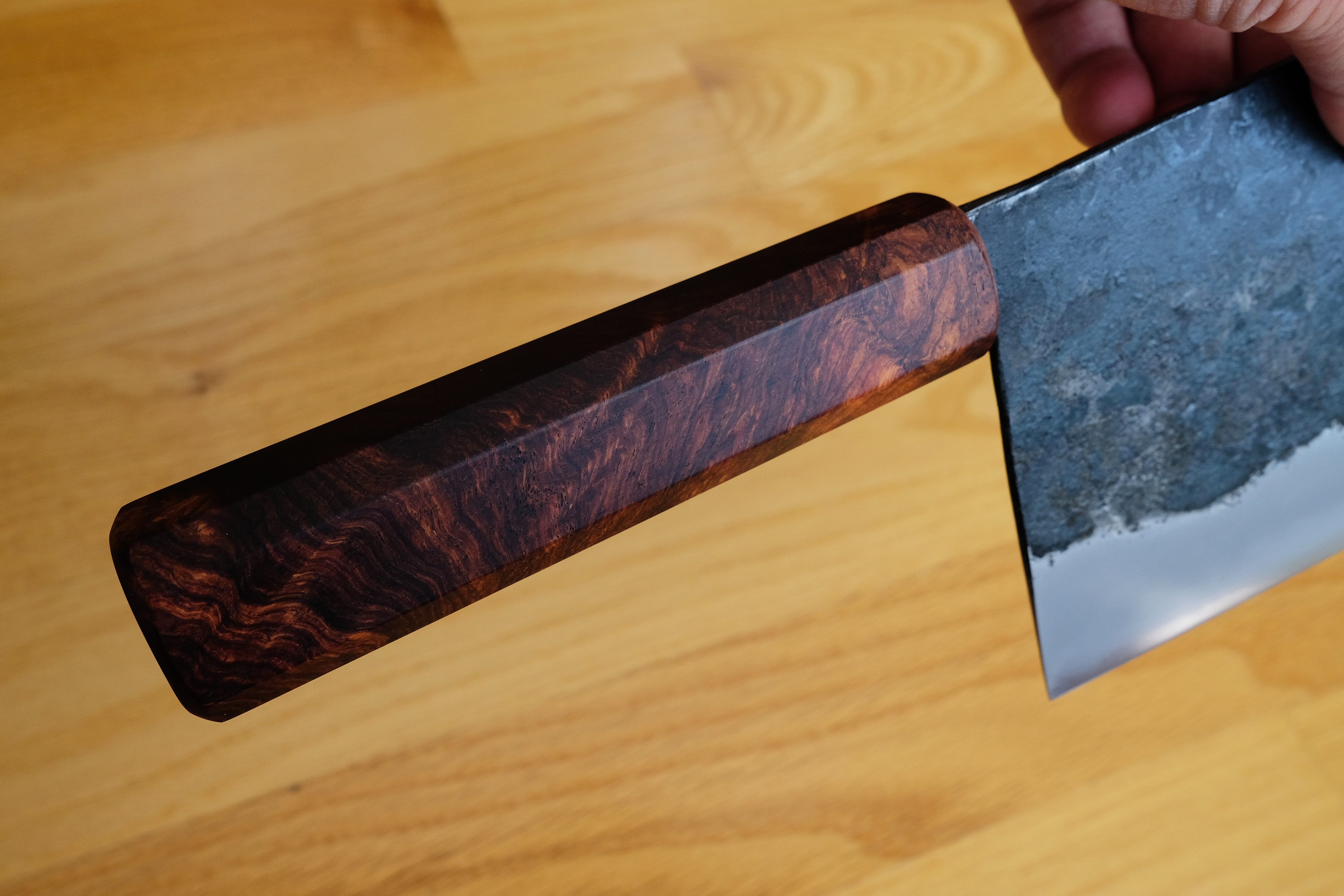

Okubo nakiri/cleaver in aogami #2 and iron clad from Michael at Knife Japan. He actually listed a gigantic 250mm long “nakiri” on the site, which looks absolutely insane. I asked for a shorter one in my favorite size, 210x90 with no other requests, and Michael made it happen.

The knife was a giant rustic beast. Fat spine, thick forge scale, coarse convex grind, and with what looked like a half tree branch shoved onto the tang for a handle.

Out of the box was actually a decent performer, but that’s beside the point. That’s not why I bought this knife. I had bigger plans in store.

The Plan

The goal was to have a blend of original gritty character of the cleaver, while also giving it some refinement with a polish and a new handle that would actually allow it to fit in my knife drawer.

Tang Work

To fit the new handle, I had to adjust the tang a bit.

The stock tang had a bulge partway down. The spine thickness near the choil was about 5mm, while the thickest part of the tang was around 7-8mm. And it was offset by a bit.

Straightened out the tang.

Ground down the excess, while trying to retain as much metal as possible. Enough so that I could allow for a decent fit up of the handle later down the line without needing an oversized tang slot. Also shortened it to fit a stubby handle.

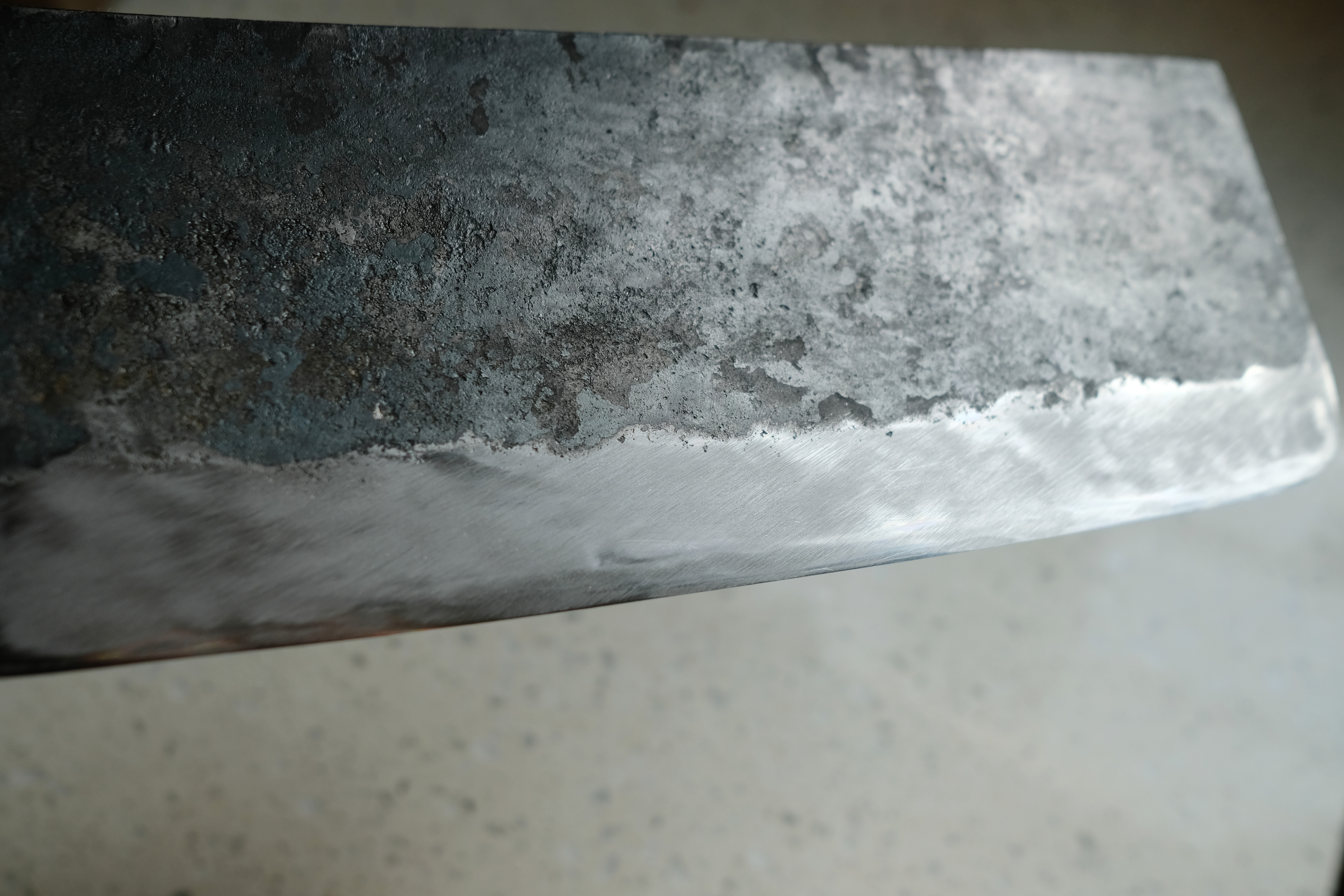

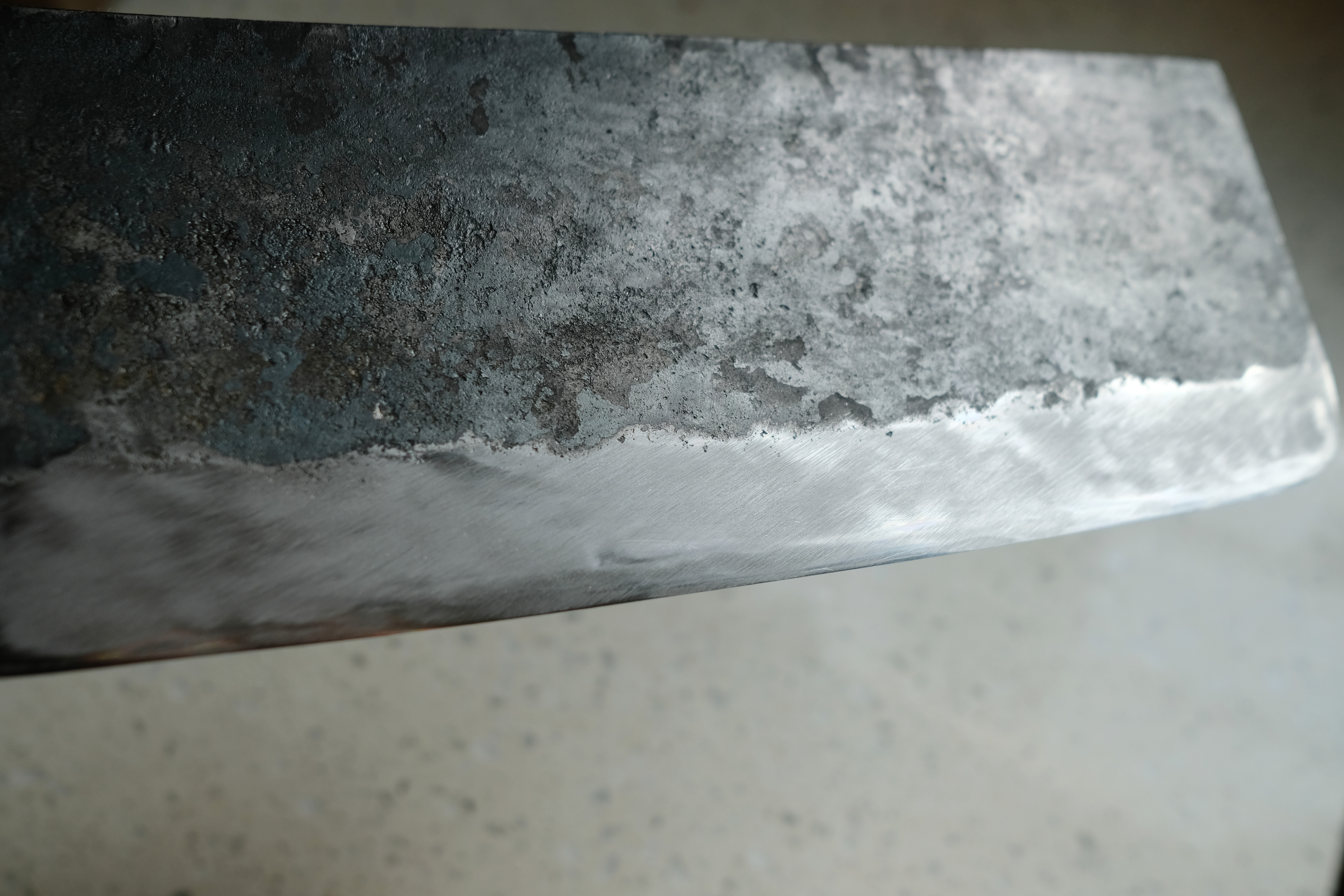

Thinning and Polishing

Stock grind was coarse.

Some low spots that needed to get worked out.

The Knife

Okubo nakiri/cleaver in aogami #2 and iron clad from Michael at Knife Japan. He actually listed a gigantic 250mm long “nakiri” on the site, which looks absolutely insane. I asked for a shorter one in my favorite size, 210x90 with no other requests, and Michael made it happen.

The knife was a giant rustic beast. Fat spine, thick forge scale, coarse convex grind, and with what looked like a half tree branch shoved onto the tang for a handle.

Out of the box was actually a decent performer, but that’s beside the point. That’s not why I bought this knife. I had bigger plans in store.

The Plan

The goal was to have a blend of original gritty character of the cleaver, while also giving it some refinement with a polish and a new handle that would actually allow it to fit in my knife drawer.

Tang Work

To fit the new handle, I had to adjust the tang a bit.

The stock tang had a bulge partway down. The spine thickness near the choil was about 5mm, while the thickest part of the tang was around 7-8mm. And it was offset by a bit.

Straightened out the tang.

Ground down the excess, while trying to retain as much metal as possible. Enough so that I could allow for a decent fit up of the handle later down the line without needing an oversized tang slot. Also shortened it to fit a stubby handle.

Thinning and Polishing

Stock grind was coarse.

Some low spots that needed to get worked out.

Last edited: